Reliable waterway operations depend on consistent depth and predictable navigation, which is increasingly important for port and river maintenance in Mali. Seasonal water-level shifts, rapid sediment movement, and increasing transport demand mean operators cannot rely on temporary clearing methods or irregular maintenance cycles. When channels narrow or berthing access declines, the impact on cargo flow, community transport, and operational schedules is immediate.

This is why many project owners now turn to professional dredging services. The difference shows in accuracy, equipment capability, and the ability to manage large volumes of sediment safely and efficiently. In a setting where even small depth changes can disrupt traffic, structured maintenance delivered by experienced contractors has become essential.

As a local specialist, Dredge Works Mali provides Mali-specific dredging services tailored to these conditions. The company focuses on restoring navigation depth, stabilising river sections, and supporting port operations with equipment and methods suited to Mali’s rivers. Throughout this blog, we’ll walk you through the role of professional dredging in practical terms, so operators can identify the right time and approach for maintaining critical waterway infrastructure.

Understanding Mali’s Rivers and Ports in Real Operating Conditions

Effective port and river maintenance in Mali begins with understanding how the Niger and Bani river systems behave throughout the year. These waterways support transport, trade, and community movement, but they also shift quickly. Sediment can accumulate within days during seasonal transitions, and water levels often drop earlier than expected during dry periods. This creates a working environment where depth reliability becomes a continuous operational priority.

Key transport hubs such as Mopti and Koulikoro face recurring issues related to siltation, narrow channels, and shallow berthing depths. These changes are not gradual. Operators regularly report noticeable depth loss after peak flow periods, which affects vessel loading, schedules, and fuel efficiency. In many cases, inconsistent depth is the primary cause of transport delays along these river corridors.

Because conditions change rapidly, informal clearing methods are rarely effective over the long term. Consistent monitoring and structured maintenance are necessary to keep navigation routes open. This is where Mali dredging services play a significant role. Professional assessments identify early signs of obstruction, enabling operators to plan interventions before the waterway reaches a point where flow is restricted.

As a local specialist, Dredge Works Mali understands these environmental patterns and aligns its work with actual field conditions. Their team evaluates sediment behaviour, flow changes, and access limitations to determine the right moment to deploy professional dredging services. This approach helps ports, municipalities, and transport operators maintain predictable river operations year-round.

The Operational Risks of Delayed or Inadequate Maintenance

Delaying port and river maintenance in Mali often leads to operational issues that are far more costly than planned intervention. Sediment buildup changes vessel routes, reduces draft clearance, and disrupts transport schedules. Many operators begin to notice these problems only after cargo delays or unexpected grounding events occur, typically when manual clearing is no longer effective.

Even a small change in depth can produce measurable impacts. Inland transport studies show that a reduction of just a few centimeters can slow vessel movement and increase fuel use, especially in narrow sections near Mopti and Koulikoro. When multiple trips are affected, the overall logistics cost increases significantly. This is one of the clearest signals that professional Mali dredging services are needed rather than small-scale fixes.

Another risk is the compounding effect of sediment accumulation. Once a shallow zone forms, flow velocity decreases, and additional material begins to settle in the same area. This pattern can turn a manageable obstruction into a complete navigation blockage within a short period. Emergency interventions cost more because equipment must be mobilized quickly, and dredging volumes are higher.

Safety concerns also arise when water depth becomes unpredictable. Vessel grounding, cargo damage, and increased insurance exposure are common outcomes of neglected maintenance. For operators, these risks affect both operational continuity and financial planning.

Specialist contractors offering Mali dredging services help prevent these issues by identifying early indicators and addressing them with structured excavation methods. Dredge Works Mali supports this process by assessing high-risk sections, estimating sediment volumes, and recommending the required level of intervention. This ensures that maintenance actions are taken before disruptions reach a critical level.

When Professional Dredging Services Become Necessary

There are specific operational conditions in which relying on Mali’s dredging services is the only practical and cost-effective option. These conditions are common in Mali’s river systems due to rapid sediment transport and seasonal water-level fluctuations.

One of the strongest indicators is accelerated sediment accumulation. During transitional months, the Niger River can experience 20 to 35 percent higher sediment deposition, which causes sudden drops in navigation depth. When this happens, informal clearing methods cannot keep up. Consistent, controlled excavation by Mali Dredging Services is necessary to maintain safe vessel access.

Another key indicator is reduced vessel performance. Even a small 10-15 cm loss in depth can affect cargo loading, travel speed, and route selection. When operators begin adjusting schedules or limiting vessel capacity, the waterway has already reached a point at which professional dredging services are required. In many cases, early deployment of Mali dredging services prevents larger operational losses.

A third factor is the size of the dredging requirement. In Mopti, Koulikoro, and similar sections, maintenance cycles often involve 2,000 to 5,000 cubic meters of sediment. These volumes cannot be removed manually. They require structured excavation, pumping systems, and controlled disposal, all of which fall under the capabilities of Mali dredging services delivered by qualified contractors.

A fourth indicator is the spread of the obstruction. When siltation affects long sections of a channel, consistent depth restoration is only possible through professional methods. Without proper equipment, the risk of uneven dredging and repeated blockages increases significantly.

At this point, the need for professional dredging services in Mali becomes clear. Dredge Works Mali provides assessments, sediment analysis, equipment selection, and full operational support to ensure dredging restores reliable navigation depth. Their experience with local river conditions allows operators to act early and avoid expensive emergency interventions.

Dredging Technologies That Work for Mali’s River Conditions

Selecting the right technology is one of the most important steps when planning port and river maintenance in Mali. River conditions vary across Mopti, Koulikoro, and upstream channels, so operators need solutions that match sediment type, access limits, and project scale. This is why many organisations rely on Mali dredging services, which offer equipment specifically suited to these environments.

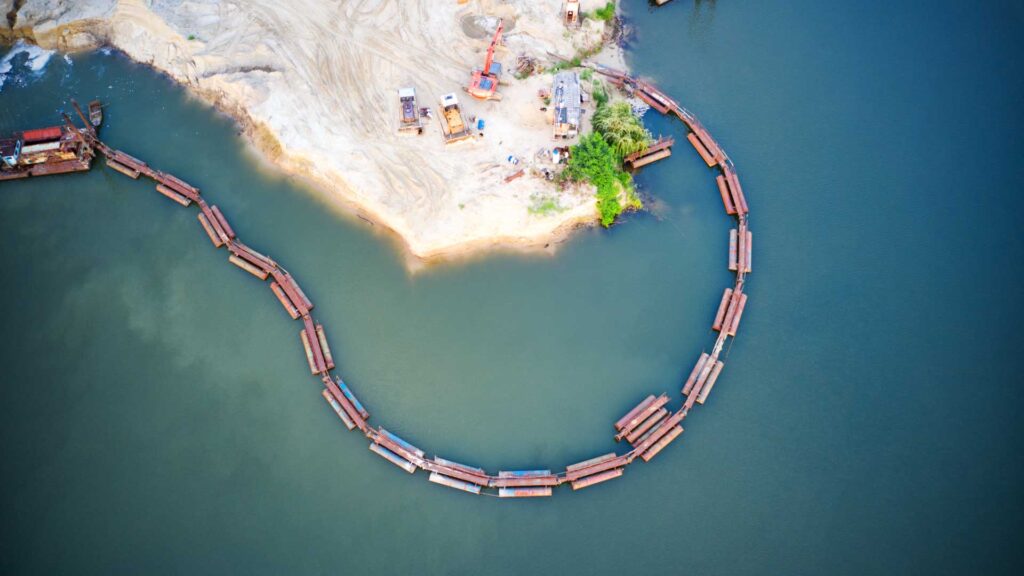

Cutter suction systems are among the most effective technologies in the region. These systems deliver controlled excavation and consistent depth control, which is essential in channels with compacted sediment. When operators rely on professional dredging services, cutter suction units are often recommended for restoring navigation depth over long stretches.

Pump and pipeline systems are another common choice. Many sections of the Niger and Bani rivers accumulate fine sediment that can be moved efficiently through pumping. This method is widely used within Mali dredging services because it allows material to be transported to approved disposal points without disrupting vessel traffic. It is also suitable for projects that require high-volume excavation within a short maintenance window.

Excavator-based dredging also plays a major role. Shallow areas, landing points, and community access zones often require targeted removal rather than full-scale excavation. Excavator-mounted pumps and long-reach booms enable precise work in locations where floating equipment cannot operate. This approach is frequently used by Mali dredging services to support small ports and community landing sites.

Another practical factor is equipment mobility. Transport routes across Mali are challenging, making modular, truck-mobilized dredging systems more suitable than large vessels. Professional contractors offering Mali dredging services are familiar with these constraints and select equipment that can be mobilized and assembled quickly to reduce delays.

Dredge Works Mali integrates all these technologies into its service offering. The company evaluates sediment behaviour, water depth, river width, and accessibility before recommending the correct method. This ensures that the selected equipment supports efficient, safe port and river maintenance in Mali, with predictable outcomes for project owners.

Practical Scenarios Where Professional Dredging Becomes the Preferred Solution in Mali

Different locations in Mali face different maintenance pressures. The following scenarios reflect actual operating patterns seen along the Niger and Bani rivers and show how structured dredging support prevents disruptions and reduces long-term costs.

Scenario 1: Seasonal Channel Restoration in Mopti

During the transition from high to low water, the Mopti region often experiences sharp depth loss along active navigation corridors. Sediment can accumulate unevenly and create narrow passages within weeks. When depth drops below the minimum clearance, vessel operators begin reducing loads or shifting departure times. This quickly affects transport reliability and market supply schedules.

A structured dredging program restores a consistent channel profile and prevents repeated slowdowns. Cutter suction units or pump-based systems are typically used because the affected stretches can extend for several hundred meters. Dredge Works Mali provides equipment that matches these conditions and supports operators with planning that accounts for seasonal water level changes and access limitations.

Scenario 2: Berth and Access Maintenance at Koulikoro

Koulikoro faces regular silt buildup around berthing zones and turning areas. Even small depth reductions interfere with loading operations and create delays for cargo movement. Manual clearing is not effective here because the volume of material is higher and the work must be completed within a narrow operational window.

Targeted dredging ensures that vessels can approach, turn, and load without interruption. Excavator-mounted systems or compact dredges are often preferred because they can be deployed quickly and work in constrained spaces. Dredge Works Mali supports these projects by providing equipment that achieves the required depth while keeping port activity running with minimal disruption.

Scenario 3: Restoring Navigation Near Small Communities Affected by Sediment Buildup

In certain upstream and midstream areas, local communities depend on small passenger vessels and cargo boats for movement and trade. When sediment accumulates near landing points, access becomes unreliable, and transport costs increase. These locations often require precise dredging rather than large-scale excavation because the waterway is narrow and the working area is limited.

A combination of pump systems and excavator-mounted equipment is typically used to clear these sections safely. Dredge Works Mali works with local operators to assess sediment levels, plan access routes, and complete the work without affecting community activity.

Environmental and Regulatory Factors That Influence Dredging in Mali

Environmental and regulatory considerations shape how dredging work is planned and executed in Mali. River systems here support transport, agriculture, and community livelihoods, which means maintenance projects must be carried out with clear controls and predictable methods.

One major concern is turbidity, which increases when sediment is disturbed. Studies of similar West African river systems show that turbidity can increase by 25-40% during uncontrolled excavation. High turbidity affects water quality and increases the risk of sediment drifting into active fishing areas. This is why professional dredging teams use controlled excavation, calibrated pumping rates, and monitoring tools to maintain stable conditions.

A second factor is habitat sensitivity. Shallow sections near Mopti and Koulikoro are known to support seasonal fish breeding activity and community fishing zones. Even small shifts in sediment placement can change water flow and affect these areas. Field assessments indicate that poorly managed disposal can increase downstream deposition by 10 to 20 percent, which reinforces the need for engineered disposal plans.

Regulatory requirements also influence project execution. Local authorities often request basic environmental management plans, disposal location approvals, and safety documentation. These steps are intended to reduce the risk of uncontrolled sediment spread and to ensure that maintenance work does not disrupt nearby communities. Operators who proceed without proper planning often face delays or corrective work orders.

Professional contractors help meet these expectations through structured planning and consistent record-keeping. Dredge Works Mali prepares environmental considerations as part of its project approach. This includes selecting disposal sites, managing turbidity limits, monitoring excavation progress, and coordinating with local authorities. These steps reduce project risk and help maintain compliance throughout the maintenance cycle.

Procurement, Contracting, and KPIs for Dredging Projects in Mali

Procurement teams in Mali often face challenges when evaluating dredging proposals because equipment capability, mobilization timelines, and disposal planning vary widely between contractors. A clear set of requirements helps prevent scope gaps and ensures that the selected provider can deliver the expected results within the river conditions of Mali.

The first requirement is a defined scope with measurable depth targets. Even a variation of 10 to 20 centimeters in final depth can affect vessel performance, so procurement teams should request baseline surveys, target profiles,s and expected tolerances. This prevents disputes once the project reaches completion.

A second requirement is mobilization clarity. In Mali, equipment often travels long distances over road networks, and delays are common when transport plans are unclear. Contractors should present estimated mobilization time, required access routes, and assembly needs. Professional operators like Dredge Works Mali provide mobilization plans that outline equipment configuration, transport method, andon-sitee readiness timelines.

A third requirement concerns disposal planning. Sediment volumes in maintenance projects can range from a few hundred cubic meters to more than 5,000 cubic meters, depending on the site. Procurement documents should specify disposal expectations and require contractors to propose safe and approved locations. This step reduces environmental impact and ensures compliance with local authorities.

To evaluate proposals, procurement teams often rely on a simple KPI based scoring model. Useful KPIs include depth accuracy, daily production rates, turbidity limits, and adherence to safety protocol. Recording these KPIs during the project allows operators to verify performance and request adjustments when needed.

Professional contractors help streamline this process. Dredge Works Mali provides structured proposals that include method statements, equipment specifications, environmental considerations, and expected production rates. This level of detail simplifies evaluation and gives project owners confidence that the contractor can work within Mali’s logistical and environmental constraints.

Cost Drivers, Budget Planning, and a Simple ROI Model for Dredging in Mali

Budgeting for port and river maintenance in Mali requires a clear understanding of what actually drives project cost. Prices do not vary randomly. They follow consistent patterns linked to sediment volume, mobilization distance, equipment type, and the level of environmental control required. When these factors are identified early, project owners can estimate realistic budgets and avoid unexpected cost escalations.

The first major cost driver is mobilization. Moving dredging equipment across Mali’s road network often represents 25 to 35 percent of the total project cost, especially for sites located far from major transport corridors. Modular units reduce this cost because they can be transported in smaller loads and assembled on site. Contractors like Dredge Works Mali rely on modular systems for this reason.

A second cost driver is production capacity, which refers to how much material the equipment can remove per hour. Higher capacity units reduce the overall working days required. For example, a pump based system with a capacity of 300 cubic meters per hour can complete a 3,000 cubic meter task in roughly 10 operating hours, although real conditions usually extend this period to two or three days. Smaller excavator-based units take longer and increase daily operating costs.

A third cost factor is disposal logistics. Moving material to approved sites requires pipelines, loading equipment,t or transport plans. Disposal can account for 20 to 30 percent of a project budget when distances are significant or when environmental controls are required.

A simple ROI model helps project owners justify their investment. When siltation forces vessels to reduce load, even a 10 percent loss in carrying capacity can increase transport cost per ton. If a port processes 15,000 tons per season, reduced capacity can add measurable cost. Restoring depth through scheduled dredging often recovers more value than the project cost itself. Many operators find that the savings from improved vessel movement offset dredging expenses within a single season.

Dredge Works Mali supports this analysis by providing sediment estimates, production rate projections, and cost ranges during the planning stage. These inputs help operators build budgets that reflect actual conditions and select the method that delivers the strongest return on investment.

Conclusion

Effective port and river maintenance in Mali depends on making decisions before siltation disrupts operations. Seasonal shifts, fast sediment build-up, and expanding transport needs create conditions where only structured and professional dredging services can maintain safe and reliable waterways. When channels narrow or berthing depth declines, the operational cost of delays often becomes higher than the cost of maintenance itself.

Using the right method at the right time is the difference between short-term fixes and long-term stability. Predictable depth, safe vessel movement, and consistent navigation all rely on a maintenance plan that uses qualified equipment and experienced teams. This is where specialised Mali dredging services deliver measurable value, especially for port authorities, logistics operators, and community transport networks.

Dredge Works Mali provides the technical capacity, equipment,t and planning required to complete dredging work under real local conditions. Their approach aligns with the practical challenges found across Mali’s rivers and ensures that projects are delivered with accuracy, compliance, and long-term reliability.For any operator seeing early signs of depth loss or increasing sediment pressure, this is the stage at which engaging professional Mali dredging services delivers the strongest operational and financial returns. Dredge Works Mali can review the site, propose a suitable method, and help restore dependable waterway performance.